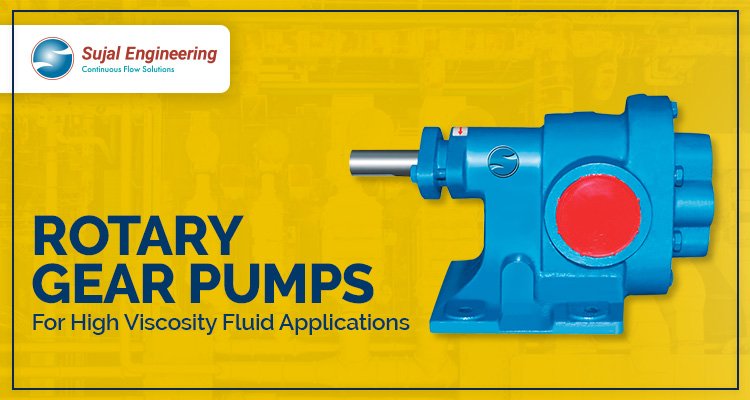

Rotary Gear Pumps – For High Viscosity Fluid Applications

In today’s topic, we are discussing on our rotary gear pumps.

How it will use to transfer high viscosity liquids in different industrial applications?

Let’s start with what is high viscosity liquids?

A liquid with a high internal resistance to flow is described as having a high viscosity. liquids with long-chain molecules (such as plastics) have a much higher viscosity.

Examples of high viscosity liquids:

Abrasive resins, urethane coatings, roof tar emulsion, acidic mud slurries, ceramic resin with sand content and many types of adhesive are known as a high viscosity liquid.

Many industries have to work with these high viscosity liquids because it’s very important for their manufacturing process.

For transferring these high viscosity liquids these industries required very fast, efficient and durable pumps which is very effectively transfer high viscosity liquids. It is nearly impossible for manufacturing industries to work without pumps with these liquids.

How these industries find excellent pumps for their industries?

To solve this problem many industries started to purchase pumps to transfer high viscosity liquids.

But they don’t have perfect knowledge about the pumps so they are failed to purchase efficient pumps to give them desire result for their industries.

To solve this problem Sujal Engineering has manufactured rotary gear pumps to transfer high viscosity liquids.

Sujal Engineering is an exceptional manufacturer of industrial pumps. Our pumps are very efficient to handle different kind of liquids like hot or cold, clean or contaminated, thick or thin.

We have vast experience to manufacture a wide range of pumps for different industrial applications.

Let’s talk about our rotary gear pumps:

Sujal Engineering is a leading manufacturer of SGP Series – Known as Rotary Gear Pump.

We are the best rotary gear pumps manufacturing from last many years. Our pump is multi-purpose rotary gear pumps with double helical gears are a self-priming pump with 5 meters left suction.

It is specially used for the handling of high viscosity liquids. Our rotary gear pump is manufactured under the guidance of an experienced person using advanced technology and quality-tested components.

Working Principle:

A rotary gear pump uses the positive displacement principle to pump the liquids. The pump has a casing with dual gear and crescent which is assembled in the curved shape. While in a process when the rotor gear started to turn, the gear rotates with the teeth beginning to mesh. The space between the gears and the meshing action which pump the fluid to displaces that is why the positive displacement name is given.

Three pieces of design make the pump easy cleanable and maintainable.

Technical Specification:

Type: Double Helical Rotary Gear Pump

Capacity: up to 195 m3/hr

Head: up to 100 Meter

Pressure: up to 10 kg/cm2

Size: 12 mm to 200 mm

Speed: up to 1500 rpm

Temperature: up to 200°C

M.O.C.: CI, CS, SS304 / 316, SS 304 L/316L, Alloy 20, Hast alloy B or C, CD4MCU, etc

Sujal Engineering has vast experience to manufacture rotary gear pump for different industrial applications. Our rotary gear pumps are specially manufactured to handle or transfer high viscosity liquid. Our top-notch engineering team ensures we produce the best pumps for our clients. For any special requirement, feel free to contact us.

Read More:

- Industrial Pumps For Chemical Processing Applications – A Brief Guide

- Best Pumps For Pumping Abrasive Materials – Informative Guide

- Top Industrial Pumps – Applications & Technical Specification [INFOGRAPHIC]

- Chemical Pumps for Petrochemical Applications – A Definitive Guide

- Industrial Pumps For Chemical Plants – Transferring Aggressive Fluids